The use of robots in electronics manufacturing requires extensive knowledge of automation and a solid understanding of the particular difficulties of this sector. Because electronic components must be positioned quickly and accurately, human assembly is labor-intensive and slow. Robots are the only way to achieve the speed and accuracy required for modern production. This man-made technology is finding its way into several industries like agriculture, supply chain, defense, etc.

Not only that, robotics is becoming necessary to maintain efficiency and quality as electronic components become smaller. Studies note that robots are now used 15% more frequently in the electronics industry. Automated systems can reduce production errors by up to 80%, increasing efficiency and reducing costs. Read on to learn more about it.

What Does Robotics in Electronics Mean?

Robotics in electronics means using robots or robotics in various technical processes. This includes designing, constructing, and other tasks related to electronics.

This is made possible by merging the fields of mechanical engineering, electronics, and computer science to create a robot that can automate processes, perform tasks, and assist humans in electronics-related activities.

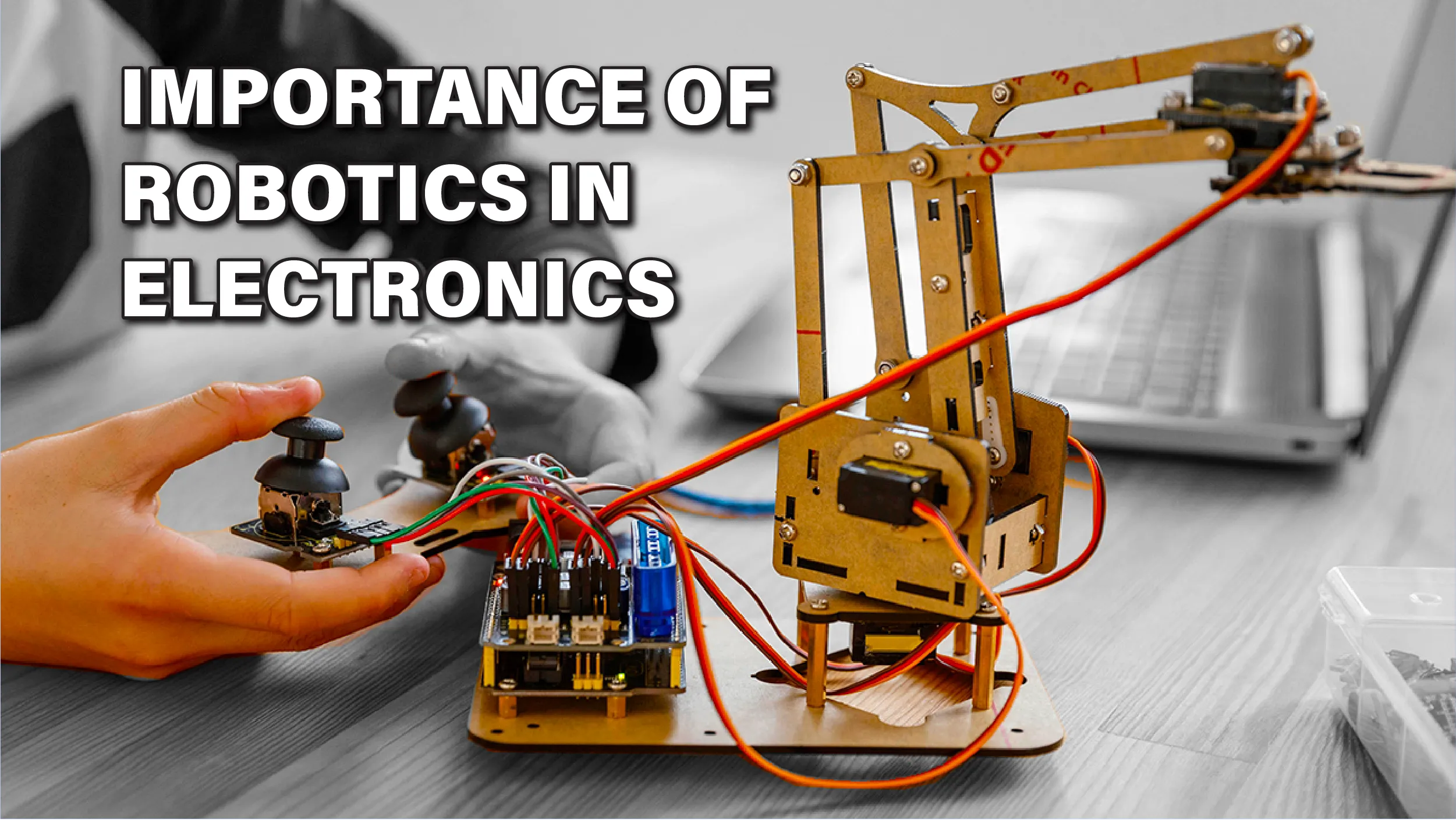

Importance of Robotics In Electronics

Automated production offers numerous advantages in terms of cost, quality, flexibility, and safety. Unlike humans, automated systems can perform repetitive tasks without fatigue, breaks, or errors, resulting in higher productivity and longer operating times.

Robots ensure consistent performance, produce identical and high-quality electronic assemblies, increase production, and minimize manufacturing errors, material waste, and returns. In addition, robotic arms are typically flexible, lightweight, and easy to deploy, so they can be adapted to different applications without requiring significant changes to the production line layout, saving time and space.

Apart from improving production and precision, automated robots also reduce safety risks by performing tasks in hazardous environments or near machinery, protecting human workers from potential harm.

Also Read: What Is a Semiconductor Chip and What are Its Different Types?

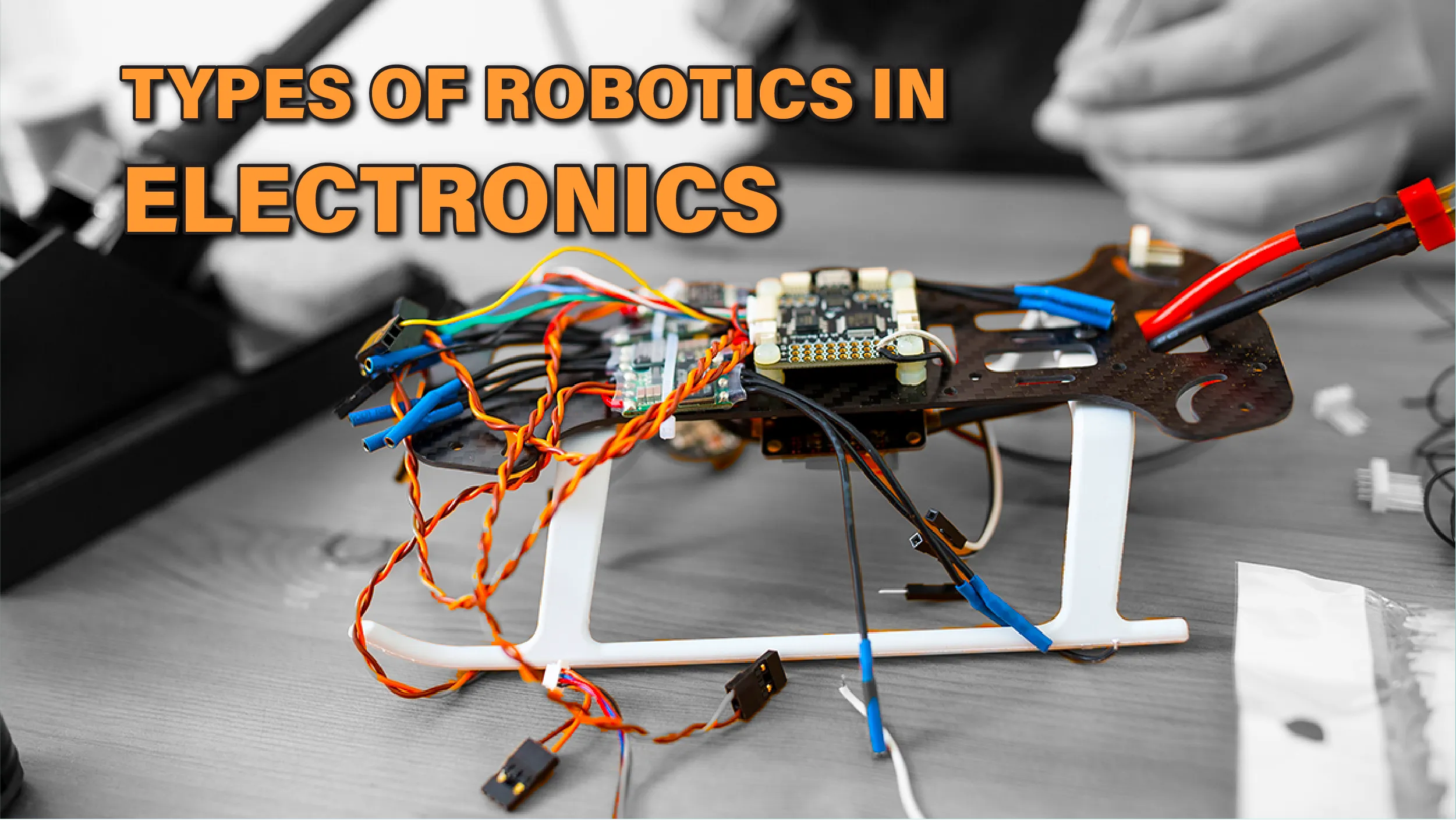

Types of Robotics In Electronics

- Pick and Place Robots: These robots play a big role in making electronics. They grab electronic parts from one spot and put them on circuit boards or other devices with great care. To handle small parts without breaking them, these robots often use suction cups at the ends of their arms.

- Collaborative Robots (Cobots): In electronics, cobots help workers do things like put things together, run tests, and check quality. They have sensors and safety features to make sure they don’t hurt anyone while working together.

- Inspection Robots: These robots check the quality of electronics as they’re made. They have cameras, sensors, and other tools to find problems, make sure products are good, and check that everything meets the rules.

- Mobile Robots: These robots can move around on their own. In electronics, they help move stuff, keep track of what’s in stock, and handle shipping. They use sensors and maps to find their way around tricky spaces.

- Robotic Arms: Robotic arms are flexible robots that can move in many ways. In electronics, people use them to solder, put things together, and run tests. You can program these arms to move how you want and handle electronic parts with great care.

- Unmanned Aerial Vehicles (UAVs): People in many fields, including electronics, use UAVs like autonomous aircraft, which most folks call drones. In electronics, UAVs help with looking at things from above, keeping an eye on stuff, and checking out areas. They take pictures and collect info from different spots and heights, which gives people useful data to study and make choices.

- Robotic Exoskeletons: Robotic exoskeletons are machines you can wear to help you do hard physical work. In electronics, workers use exoskeletons when they need to lift heavy things or do the same moves over and over. This helps keep them safe from getting hurt and makes their work easier on their bodies.

What is the Use of Robotics In Electronics?

Here are some important use cases of robotics in electronics:

- Efficiency and precision: Robotics automates manufacturing processes in the electronics industry, increasing efficiency and precision. Robots can perform repetitive tasks quickly and accurately, resulting in greater productivity and fewer errors.

- Advanced assembly and testing: Robots can perform complex assembly and testing tasks in the electronics industry. They can precisely handle, place, and align small and delicate components.

- Quality control: Robotics enables advanced quality control in electronics manufacturing. Robots can inspect, detect defects, and ensure product quality, resulting in higher customer satisfaction.

- Safety: Robots can be used in hazardous environments or in situations where human intervention is too risky. In electronics manufacturing, robots can handle hazardous materials or processes, risking human safety.

- Innovation and research: Robotics in electronics opens up new opportunities for innovation and research. It enables engineers and scientists to research new technologies, develop prototypes, and test new concepts in electronics.

- Remote monitoring and control: The ability to monitor and control robots remotely makes global electronics manufacturers more efficient. It enables centralized control of the production line as well as real-time adjustments and optimizations.

Sparkling Future Aspects of Robotics in Electronics

As the world is speeding in the direction of artificial intelligence (AI), humanoid robotic systems, etc, the future of robotics in electronics seems electric. As technology evolves, we can expect more sophisticated robots that integrate advanced AI, machine learning, and IoT capabilities, further automating complex processes and enabling real-time data analysis and decision-making.

Robotics integration will advance the industry by streamlining manufacturing, cutting costs, and encouraging the creation of new goods and technologies. Robotics will open up new opportunities as it develops, making electronics manufacturing safer, more effective, and much more flexible to the constantly shifting demands of the market. Robotics in electronics has a bright future ahead of it, one that could revolutionize the way we create, use, and interact with electronics.