Industrial robots are highly versatile and efficient tools used in various industries, including manufacturing, machinery, and assembly. These fully automated, programmable machines can move on three or more axes and perform tasks such as loading and unloading, arc welding, spot welding, and painting investment casting. They share similarities with humans in having multiple joints, articulations, and manipulators that can be programmed to perform specific tasks efficiently. Robotics applications in manufacturing help achieve cost synergies and reduce waste, making them ideal for heavy-duty or repetitive tasks in manufacturing, machinery, and assembly industries. Without further ado, let’s get started and understand everything about it.

Are Robots Taking Over Jobs or Empowering Us In Manufacturing?

Robots are changing the way we think about manufacturing; they are designed to move materials as well as perform a variety of modified tasks in production and manufacturing settings. They are frequently used to perform tasks that are hazardous or unsatisfactory for human laborers, such as monotonous work that causes fatigue and may result in wounds due to the worker’s negligence.

Industrial robots can significantly improve product quality. In each activity, applications are carried out with precision and consistency. This level of dependability can be difficult to achieve in another way.

Industrial robots require a significant investment, but the benefits outweigh the costs. As a result of their efficient operation in manufacturing, industrial robots are worth investing in. In this article, we’ll look at some crucial applications for our co-bots.

How are Robotics Used in Manufacturing?

Robotics is extensively used in manufacturing for various purposes:

- Material Handling: Robots handle tasks like picking, placing, and transferring materials, boosting efficiency and reducing injury risks.

- Assembly and Production: Crucial in assembly lines, robots perform precise tasks swiftly, reducing errors and enhancing productivity.

- Quality Control: Robots inspect and test products for defects, ensuring consistent quality and customer satisfaction.

- Welding and Cutting: Industrial robots provide precise control in welding and cutting processes, ensuring high-quality results.

- Packaging and Palletizing: Robots efficiently handle packaging and palletizing tasks, reducing manual labor.

- Collaborative Robots (Cobots): Designed to work alongside humans, cobots assist in various tasks, promoting flexible and efficient collaboration.

- Data Collection and Analysis: Robots with sensors and IoT capabilities collect data for analysis, enabling informed decision-making and process improvement.

- Labor Shortage Mitigation: Robotics automates repetitive tasks, addressing labor shortages and allowing human workers to focus on more complex activities.

Leveraging robotics in manufacturing leads to increased productivity, improved product quality, enhanced worker safety, and cost savings. The evolution of robotics contributes to the digital transformation of manufacturing processes and the creation of smart factories.

Why Integrate Robots in the Manufacturing Industry?

Now that we have a fair idea about industrial robots and how they help in the manufacturing automation sector, let’s see why integrate robots in the manufacturing field.

· Increased Safety

One of the most significant benefits of incorporating robotics is safety. All business owners and plant managers must ensure the safety of their employees and the environment. Robots can now be assigned dangerous and harmful tasks. Employees will no longer be required to work with heavy objects or in dangerously hot environments. Companies will also be able to save money on workplace injuries and resulting lawsuits.

· Job Creation

Although robotics can outperform human labor in terms of efficiency, they do not eliminate jobs. Robots do not replace humans but rather create more job opportunities. Without humans, industrial robots are nothing more than simple machines. Co-bots cannot function independently and will require humans to program their tasks. Integrating robots into your manufacturing line will only improve current jobs. Your employees will be able to learn new technological and engineering skills. The benefits of industrial robots for your company and employees are limitless.

· Longer Work Hours

Industrial robots operate at a faster rate, with no need for breaks or pauses. Furthermore, robots can perform repetitive tasks at a faster rate. Your employees can now delegate time-consuming and tedious tasks to co-bots. Your employees can now concentrate on more difficult tasks. Integrating robotics into your current line process will improve accuracy and consistency across the board. Each product or material will be treated with the same level of care and precision. Companies that choose automation no longer have to worry about sick days, unexpected emergencies, or poor work quality.

Shades of Robotics In Manufacturing

Today, although most robots are used in manufacturing operations; the applications can be divided into four categories:

1. Material-handling

Material-handling applications involve robots transporting materials or work parts from one location to another. These tasks can be simple or complex, requiring a gripper designed for the part geometry. Robots are used for machine loading and unloading, ensuring efficient and accurate operations.

2. Processing Operations

Robots perform various industrial processes, such as spot welding, continuous arc welding, and spray painting, by manipulating tools. Spot welding is a common application in the US, where a spot welder is placed against car panels and frames. Arc welding involves moving a welding rod along the seam, while spray painting involves moving a gun over the surface. Other operations include grinding, polishing, and routing, using a rotating spindle tool.

3. Assembly and Inspection

Assembly and inspection are the third application areas for industrial robots. Because of the high cost of manual labor in these operations, the use of robots in assembly is expected to grow. Because robots can be programmed, one assembly strategy is to produce multiple product styles in batches, reprogramming the robots between batches. Another approach is to produce a variety of product styles in the same assembly cell, requiring each robot in the cell to identify the product style as it arrives and then execute the appropriate task for that unit.

4. Painting

In the automotive industry, industrial paint robots are primarily used to paint parts and equipment without leaving paint marks or drips. They are precise and apply the appropriate amount of paint to each piece of equipment without wasting any supplies. Paint robots, for instance, FANUC robots have recently been used to recreate original paintings outside of the automotive industry.

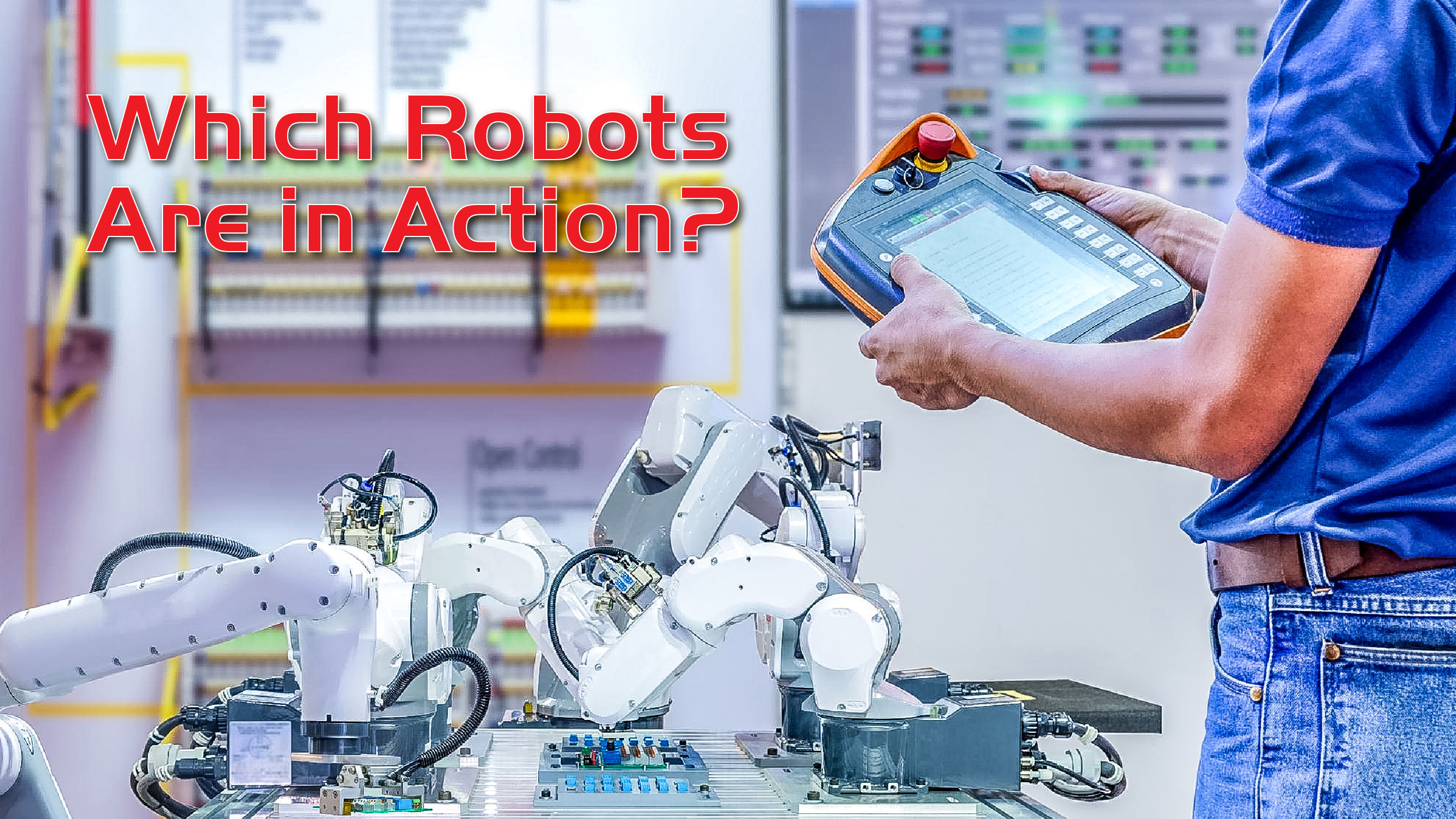

Which Robots Are in Action?

The adoption of industrial robots in manufacturing sectors has increased due to rapid advancements in robotics and automation technology. Furthermore, numerous industrial robots are being used to perform multiple tasks with repeatability, resulting in high-quality production. Industrial robots are typically classified based on their mechanical structure. This section will go over the movement of each co-bot, as well as its industry application and axis configuration.

The major robotic classification in the manufacturing industry is as follows:

· Articulated Robot

The most common type in manufacturing is articulated industrial robots. Industrial robots have several joints that allow them to perform specific movements or positions. Joints are referred to as axes in robotics, and each axis provides a degree of freedom (movement).

Up to ten or more joints, or axes, can be connected at the base of an articulated robot. They have the most degrees of freedom of any industrial robot. Articulated robots are used in applications such as packing, painting, welding, material handling, and dispensing. The most common type of articulated robot has six axes of motion.

· Delta Robots

Delta robots are made up of three arms that are connected at the base and can only move in three directions: X, Y, and Z. They are often referred to as spider robots due to their slim, lightweight arms and ability to move quickly. Some delta robots can pick up to 300 items per minute. Delta industrial robots are widely used in the pharmaceutical, food, and electronics industries. They are most commonly used for picking and packaging, but they can also be used for assembly and inspection.

· Cartesian Robot

Cartesian robots are commonly used in the production of CNC machines and 3D printers. Cartesian robots use the Cartesian coordinate system to operate on three or more linear axes (X, Y, and Z). Their coordinates enable them to move from one side to the other, in and out, and up and down. Cartesian robots operate in a rectangular workspace that allows them to access the majority of the work area. These robots are designed to work “over” their workspace, thereby saving floor space. Pick and place, dispensing, assembly, and inspection are all examples of Cartesian robot applications.

· SCARA Robots

Assembly of Selected Compliance SCARA robots are made up of two parallel joints. It comes with a donut-shaped envelope that delivers compliance in only one direction. The rotary shaft’s arm is vertical and moves horizontally. As a result, SCARA robots move faster and integrate more easily than cylindrical and cartesian robots.

· Polar Robots

Polar robots have twisted joints attached to the arm and two rotary joints with one linear joint connected to the links. These robots are Spherical robots as they have a spherical work envelope. By the way, access to this configuration of the opposing robot arm is limited within its workspace.

· Cylindrical Robots

Cylindrical robots, in general, have a cylindrical workspace and a pivoting shaft with at least one prismatic and one rotary joint attached to the links. Furthermore, due to an extendable arm and sliding, the post is moving vertically. Because of their cylindrical structure, these robots can move horizontally and vertically with their axes.

Scope of Robotic Integration

Many businesses will increasingly rely on automation to maintain minimal human contact while remaining competitive. Many industries are now adopting automation as a result of industrial robots. The majority of robotic spending is spent on industrial robots, which will most likely benefit from the current situation.

In recent years, robotics and artificial intelligence have become more sophisticated. This has created a plethora of automation opportunities in the manufacturing industry. Automation and robotics have the potential to transform manufacturing production lines, with numerous advantages for business owners, employees, consumers, and the economy as a whole.

The British Association of Robots and Automation (BARA) is leading the charge in championing these developments. BARA provides expert support to the end-user community in addition to providing a voice for the robotics and automation industries by convening with government, industry, financial, and academic institutions. The organization’s expertise and support have elevated it to the forefront of robotics and automation.

Previously, co-bots worked and performed independently of humans and other machines; however, robots can now be integrated into the workforce, and some can even work alongside human workers. Robots can now perform tasks that were previously too difficult or dangerous for humans due to advances in sensor technology.

Researchers are now working on ways to train co-bots to collect data. Data collected from robots in manufacturing will be able to help manufacturers make better decisions in the future and improve their manufacturing processes. Many researchers and businesses are currently anticipating the introduction of Artificial Intelligence (AI) and how AI will reshape the future of robotics capabilities in the coming years.

In a Nutshell

Robotic integration in production lines offers numerous benefits, including faster work, increased productivity, and job creation. However, decisions require research, understanding, and investment. As automation spreads, robots will collaborate with humans and revolutionize job roles and skill sets, requiring acceptance of changes and limitations.